The company is taking testing to the next level with its latest project designed to showcase the reliability and longevity of the HS2.4S and LB-480 pumps.

Tsurumi Pump, a global leader in innovative and durable pump technology, is excited to announce the launch of its “What a Difference a Week Makes” project. This comprehensive test revisits a project conducted in the early 2000s, reaffirming the quality of Tsurumi’s pumps in today’s evolving industry. Since then, new competitors have emerged and pump design has advanced, underscoring the importance of revisiting this test.

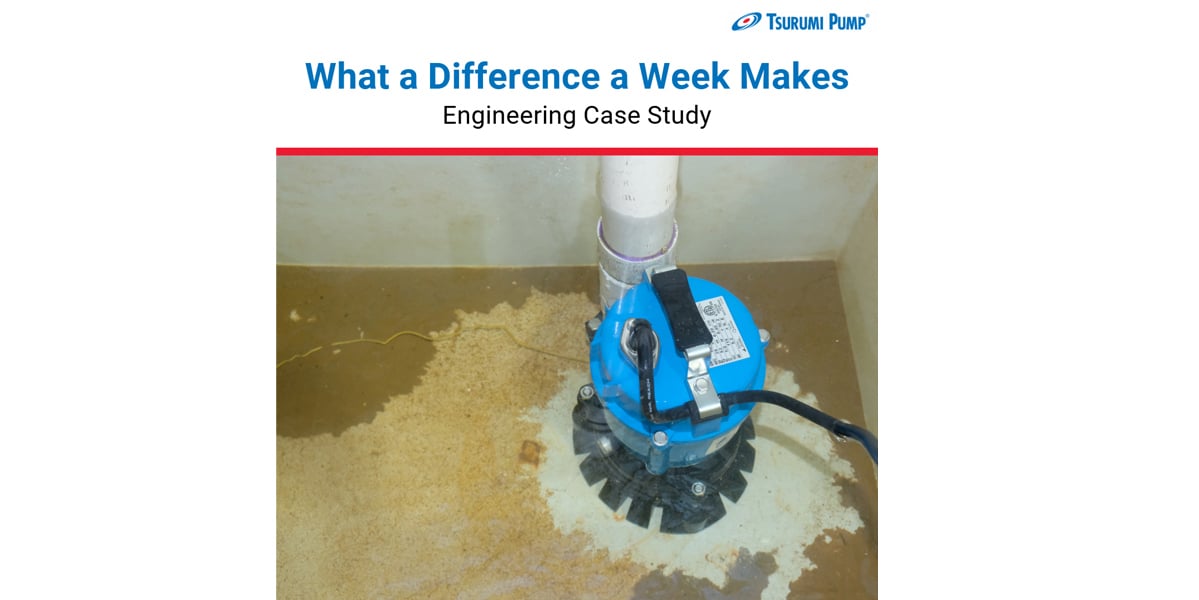

Tsurumi’s newest test will compare the HS2.4S and LB-480, with the intention of showcasing their ability to withstand the rigorous demands of modern applications. The test consists of pumping water and silica sand continuously at 100°F – 120°F through both pumps for one week.

“Our goal with this project is to confirm that the HS2.4S and LB-480 remain top-tier in terms of durability and quality” stated Pat Donahue, Applications Engineer at Tsurumi. “This test not only reflects their performance, but represents Tsurumi’s entire line of high-quality dewatering pumps, all built with the same design philosophy and attention to detail.”

Test Highlights

Tsurumi’s engineering team has meticulously designed testing procedures to ensure unbiased and accurate testing across all subjects. “Consistency is critical” said Donahue, “any variation to this could make our test sample result invalid, therefore we are confident that we have established a test that eliminates the possibility of error.”

The week-long test is designed to provide customers with actionable data and a clear visual understanding of how the HS2.4S and LB-480 perform under stress. Key metrics include:

- Pump performance comparison to evaluate if the pump can maintain level of operation throughout the span of the test.

- Vibration analysis tested at the lower bearing to aid in predicting the pump’s lifetime.

- Visual wear through photos to allow a comparison of impact in relation to wear components such as the impeller, suction cover, strainer, volute, pump casing, and oil.

Additional observations, including water temperature in the test tank, will provide insight into motor efficiency and longevity, offering valuable information to customers across industries.

“We’re committed to provide customers with confidence in their pump investment, whether they are focused on lifetime ownership or managing rental fleets” Donahue added.

Influencing Future Innovation

Beyond showcasing the HS2.4S and LB-480’s durability, this project underscores Tsurumi’s commitment to continuous improvement. This test sets the stage for future endeavors, with plans for additional stress and corrosion resistance analysis on larger products. The results will help customers make informed purchasing decisions while reinforcing Tsurumi’s dedication to excellence.