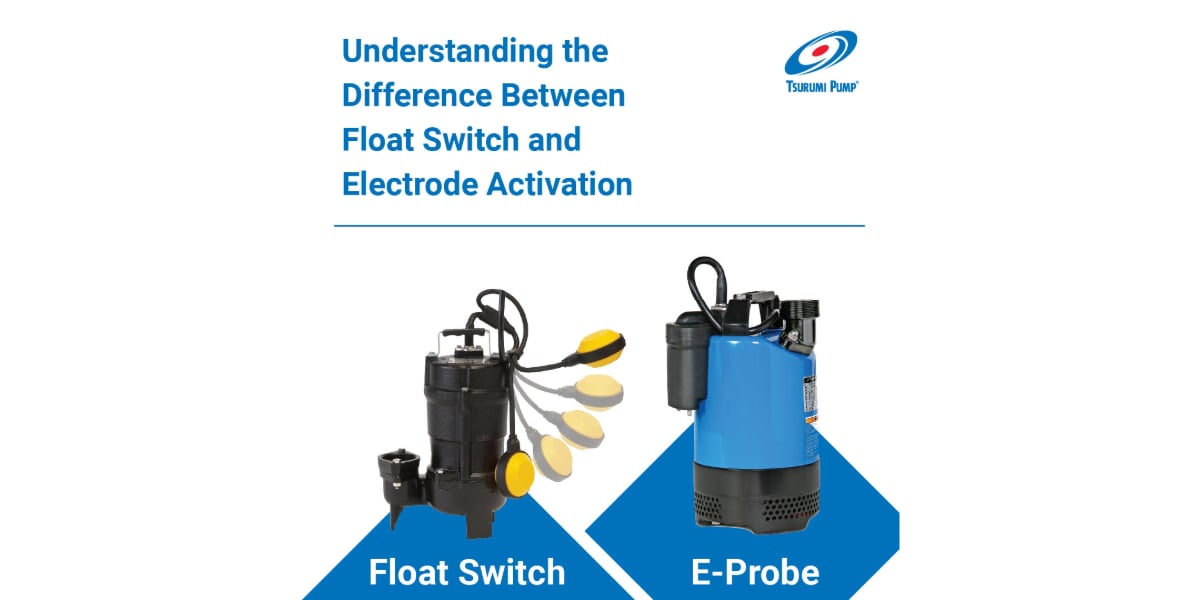

When it comes to selecting an automatic pump, understanding how activation methods work can help ensure reliable performance in the right application. Tsurumi Pump offers two types of automatic operation: float switch and electrode (E-probe) activation. While both pump designs serve the same purpose, automating pump operation based on water levels, each has unique advantages suited for different environments.

How Float Switches Work

Float switches are commonly used in sump or drainage applications, where they control a pump’s power by responding to changes in water level. The switch is housed inside a buoyant bulb that floats on the water’s surface. As the water level rises or falls, the float moves into position, opening or closing an internal switch that controls pump power.

There are two main configurations of float switches:

• Normally open: The pump remains off until water rises to a certain level, at which point the switch closes and activates the pump. This is ideal for drainage applications, such as sump pumps.

• Normally closed: The pump stays on until water reaches a set high level, causing the switch to open and deactivates the power to the pump. This is useful for filling applications where the pump is in a different reservoir/tank than the float.

Float switches offer an increased level of flexibility in placement of the start and stop heights, as it can be adjusted by altering the cable length. This allows users to fine tune their pump operation based on the needs of their specific application.

How Electrode Sensors Work

An electrode sensor detects water presence using conductivity. The sensor detects water and activates the pump when submerged. Unlike float switches, electrode sensors do not rely on mechanical movement. Instead, they use the natural conductivity of water to trigger an electrical response. Since fluids such as air and oil are non-conductive, the probe only reacts when in contact with water.

Electrode sensors are compact and mounted directly to the pump in a fixed position. They are ideal for installations where space is limited or where a floating mechanism might become obstructed.

Key Differences Between a Float Switch and Electrode Sensor

When distinguishing between a float switch and electrode sensor, there are two key differences to note:

1. Space requirements: float switches require room to move freely with the water level. In cramped or cluttered sumps, floats can get stuck on other items in the reservoir, preventing the pump from turning on or off. This could lead to ongoing operation and motor burnout. Electrode sensors, by contrast, are fixed in place and function regardless of surrounding obstacles, making them an ideal choice in confined spaces.

2. Flexibility: float switches offer a higher degree of flexibility in setting activation heights, making them ideal for applications where precise water level control is necessary. Electrode sensors typically have fixed activation points, limiting their adjustability. Float switches are restricted by their cable length, however when using adjustable clamps, the float’s height can be conveniently adjusted.

Reliability

Tsurumi’s automatic pump designs, whether equipped with a float switch or an electrode sensor, are engineered for long lasting performance. All Tsurumi automatic pumps undergo rigorous quality testing and are compliant to applicable UL and CSA safety standards. Tsurumi’s automatic pumps provide dependable operation when it matters most.